When researching air compressor types, it’s worth considering the following points:

- Application / industry requirements

- Air flow utilization

- Pressure needs

- Air quality and dryers/filters

- Usage time throughout the day

- Fluctuating air flow demand

- Future expansion plans

Piston air compressors

The most economical, least expensive air compressor to buy is the piston or reciprocating air compressor. This equipment, found in many small businesses, is very simple and robust. You can usually find a piston compressor in work, machine, body, and tire shops, as well as light manufacturing facilities.

The most economical, least expensive air compressor to buy is the piston or reciprocating air compressor. This equipment, found in many small businesses, is very simple and robust. You can usually find a piston compressor in work, machine, body, and tire shops, as well as light manufacturing facilities.

Piston compressors are relatively easy to maintain and, as previously mentioned, require minimal upfront costs. Despite their relatively low initial investment price, there are some drawbacks worth mentioning. These machines are only meant for intermittent use. They can only work at about 50-60% of their duty cycle.

This reduced runtime means piston compressors run 30-35 minutes every hour, with required downtime. These units need proper cooling time between cycles, otherwise they will overheat or break.

It is also important to understand that piston compressors create a lot of downstream oil. If not treated properly, they can damage machines utilizing compressed air.

Lastly, piston compressors tend to be very loud when operating. This noise can be hard on employees working in close proximity to the machine.

Satisfied With The Facilities At Relco (EA) Ltd Rental Services.

Mark J. Zamberg

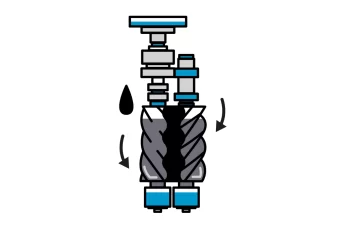

Rotary screw compressors

If your application(s) require constant compressed air supply, you should consider a rotary screw air compressor. Unlike piston compressors, these machines can handle a 100% continuous duty cycle. They’re designed and built for reliable, all-day operation.

If your application(s) require constant compressed air supply, you should consider a rotary screw air compressor. Unlike piston compressors, these machines can handle a 100% continuous duty cycle. They’re designed and built for reliable, all-day operation.

In addition, rotary screw compressors come with more options than piston machines. Depending on your needs and budget, you can opt for variable speed drive (VSD) or fixed speed engine models. Most rotary screw equipment can also be built with an integrated dryer for clean, dry air.

Furthermore, smaller screw compressors can be tank mounted. This arrangement allows for additional storage capacity, and saves on space and installation costs. When coupled with an integrated dryer, the installation is plug and play.

Variable speed drive (VSD)

Generally the most expensive option in terms of initial investment, VSD air compressors are also highly efficient. Since energy costs make up to 80% of operating any air compressor, they usually pay for themselves. In fact, you can save up to 60% with the latest generation VSD models compared to fixed speed compressors. These energy savings quickly add up to (tens of) thousands dollars per year.

If your facility has a fluctuating air demand, VSD machines are the best choice. This point is especially true if your facility operates multiple shifts during the day, where air flow increases and decreases. VSD engines match output to the required demand.

In simpler terms, the compressor senses how much flow is being used and adjusts its motor speed accordingly – allowing for the necessary output. On slower production days, VSD technology is especially handy. It eliminates wasted electricity from not constantly running at maximum capacity.

It’s also worth mentioning that many VSD compressors come with advanced monitoring and control tools to optimize performance. These optional features can collect data and analytics to determine the best operating conditions for your application(s). They also help prevent downtime and save on unnecessary maintenance costs.

VSD air compressors are becoming the norm, rather than the exception. Many customers find the annual energy savings allows them to reinvest money elsewhere.

Of course, if VSD compressors are too costly, there are other options to match your budget. Rotary screw compressors come in a wide range of sizes, and designs. If you know your air demand needs are absolutely stable, you may want to consider a fixed speed compressor.

Fixed speed

As the name suggests, fixed speed models only run at one speed throughout the day. This static operation means you’ll receive the same air pressure. It also doesn’t run at a low speed when not in use. They still make for a better option than a piston compressor if you need 100% air flow, and are designed for optimal performance.

We’re here to help

Hopefully you’ve found the information in this guide useful. If you’re still undecided on which compressor makes the most sense for you, feel free to get in touch today.